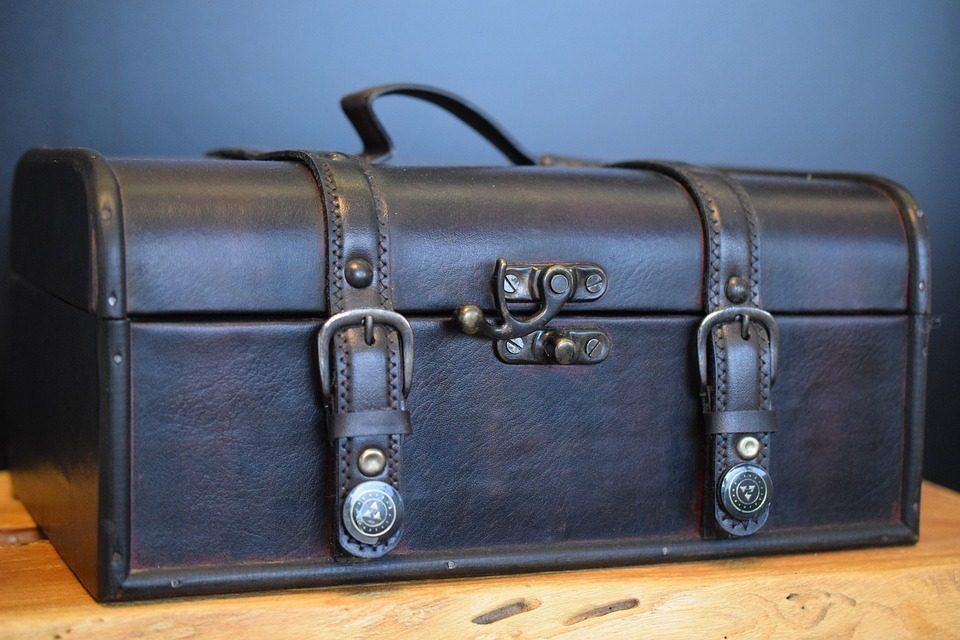

In the history of fashion, an element in particular is evergreen during time, the most versatile and sophisticated material that nature can offer us: Leather. Its scent, the infinite processes it lends itself, its versatility in adapting to all styles and personalities. Everything that somehow recalls the world of leather is fascinating.

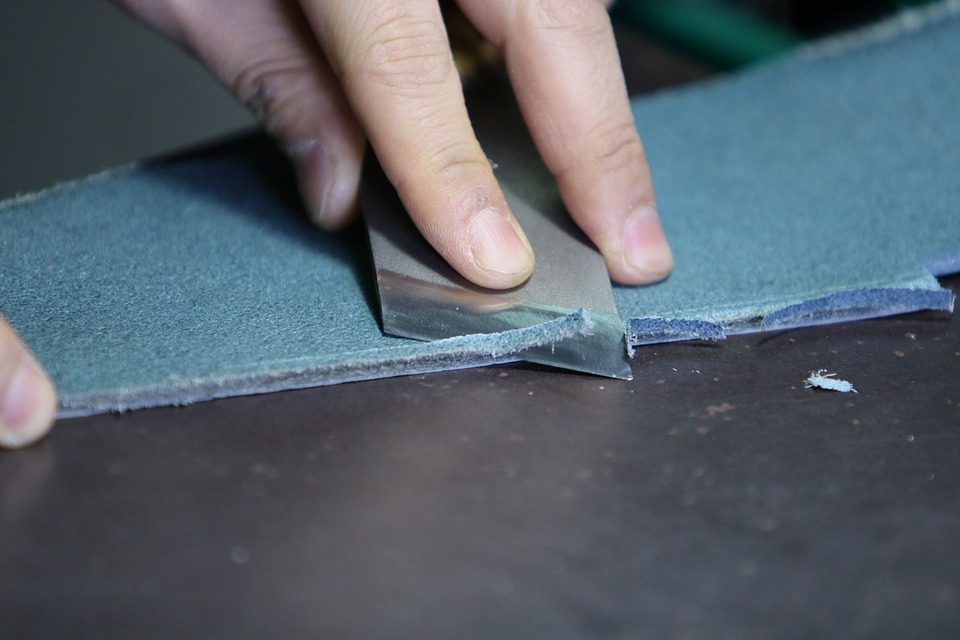

Leather is one of the first materials offered by nature that man has learned to work and use. Used in the past as a container for water and food, in modern times it has become a decorative and furnishing element, but above all, the ideal material for creating clothes, accessories, and also jewelry. For instance, leather can be used in hundreds of ways as its structure is strong and resistant and also thanks to the leather processing industry, it is now possible to work it with the most innovative techniques and products.

Over the past 40 years, the use of leather has continued to grow. Available in all possible processes and colors, thanks to leather pigments and leather softeners. Printed, engraved, or painted, everything is possible with leather. It is perfect for the creation of any type of dress, pant, shoe, skirt, jacket, bag, or accessory.

This element has thus become a must in every wardrobe also thanks to the possibility of being used and worn in every season. Born as a raw material to cover humanity from the cold, this material has now become an evergreen simbol of fashion.